Conveying Systems

Conveyors

BMH conveying systems are engineered for excellence, offering the key advantages of high reliability, exceptional durability, dust-free operation, and ease of maintenance. These systems ensure the seamless and efficient transfer of materials throughout the entire production process.

Belt Conveyors

Belt conveyors are an economical and reliable way to transfer bulk materials, such as biomass fuels, SRF/RDF, coal, cement, lime or minerals over short and long distances at various capacities with minimised environmental noise pollution.

BMH helps you to fulfil your specific usage requirements with the materials you handle providing:

- a wide selection of belt types, including special belts for demanding materials and patterned belts for larger angles of inclination,

- spillage-free solutions for loading points,

- belt centring with guide rollers and crowned pulleys,

- comprehensive belt cleaning devices,

- correct belt tension by means of screw or counter weights and

- standard safety devices (emergency stops, guards, safety nets, etc.) to ensure operational safety.

Main advantages:

- long lifetime,

- minor need for maintenance,

- high capacity,

- low maintenance and operating costs,

- high reliability,

- straightforward design and

- standard components.

Tubular Belt Conveyors

Tubular Belt Conveyors are a good choice for conveying various kinds of bulk materials over long distances at high capacities. The material lies unaffected on the conveyor belt throughout its journey between the transfer points.

The flexible design of Tubular Belt Conveyors enables horisontal and vertical curves and therefore the solution fits well to demanding sites and space-limited environments. This versatility becomes a particularly useful feature when conventional conveying systems are to be replaced in existing installations.The enclosed design prevents spillages, keeps the environment dust-free and protects the material from external impurities.

Main advantages:

- enclosed design prevents spillage and keeps the environment clean and dust-free,

- enclosed belt tube maintains the handled material undamaged and free from external impurities,

- simple and flexible layout solutions for space-limited sites,

- less cross stations and related auxiliary equipment are needed which means higher reliability and lower operating costs and

- standard components already proven to work in conventional belt conveyors.

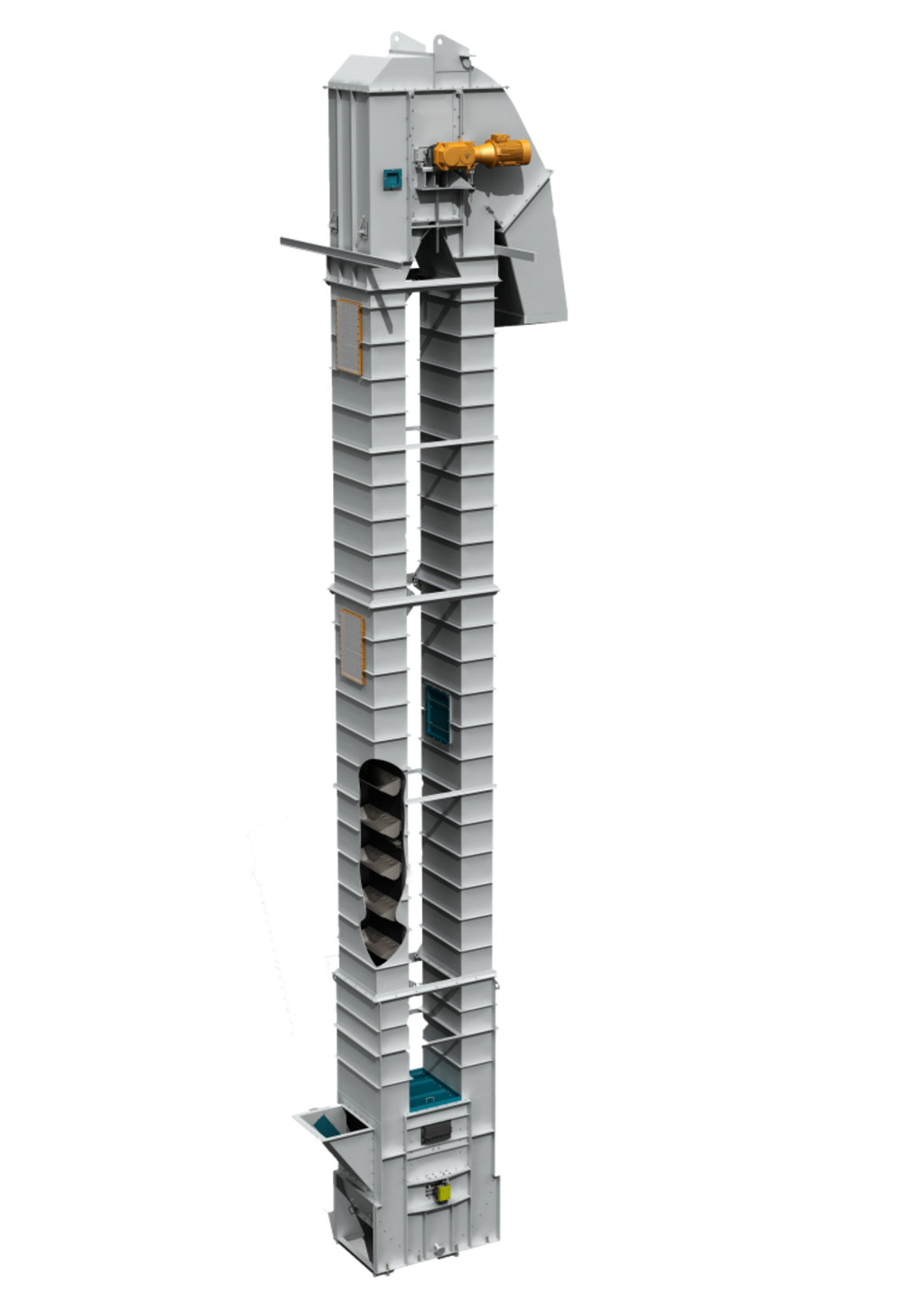

Bucket Elevators

Bucket elevators are an excellent choice particularly in locations where space is limited and material needs to be transferred high on a vertical scale.

They are capable of lifting a variety of materials up to 70 metres, ranging from dry, dusty fluff to heavy materials such as bottom ash. Bucket elevators are always custom designed to meet specific process and material requirements.

Main advantages:

- outstanding lifting capacity to high altitudes in confined spaces,

- totally enclosed construction providing dust-tight and spillage-free operation,

- specially designed buckets ensuring clean and perfect discharge,

- customised solutions based on modular engineering for fast and cost-effective installation and

- long lifetime.

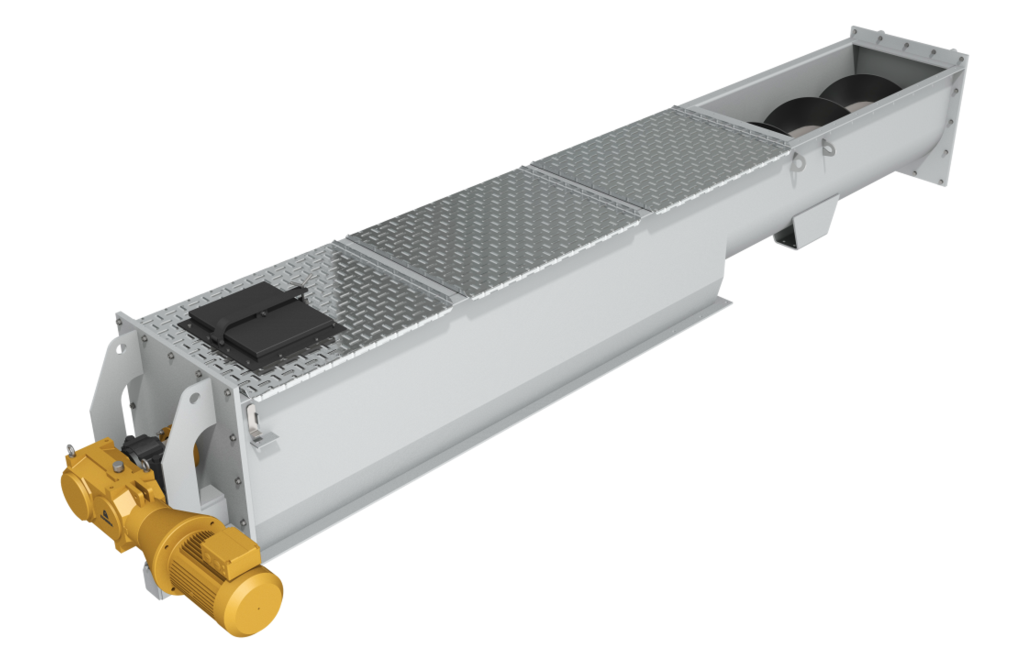

Screw Conveyors

Screw conveyors are one of the most economical ways to transfer bulk materials over short distances. Ideally they work for biomass fuels, such as wood chips, bark, agro biomass and pellets, as well as SRF, coal, peat, ash, cement, lime and minerals.

Besides transferring materials from one place to another, screw conveyors can be used for:

- feeding, dosing and mixing,

- distribution of material flow,

- cooling (double-wall special design)

- humidifying (when equipped with internal water nozzles) and

- vertical lifting of certain materials.

Main advantages:

- standard modular design,

- horisontal, inclined and vertical designs,

- tubular or U-shaped conveyor trough,

- special design flights for difficult sticky materials,

- screws with wear-resistant facing for demanding conditions and

- simple construction for easy maintenance.

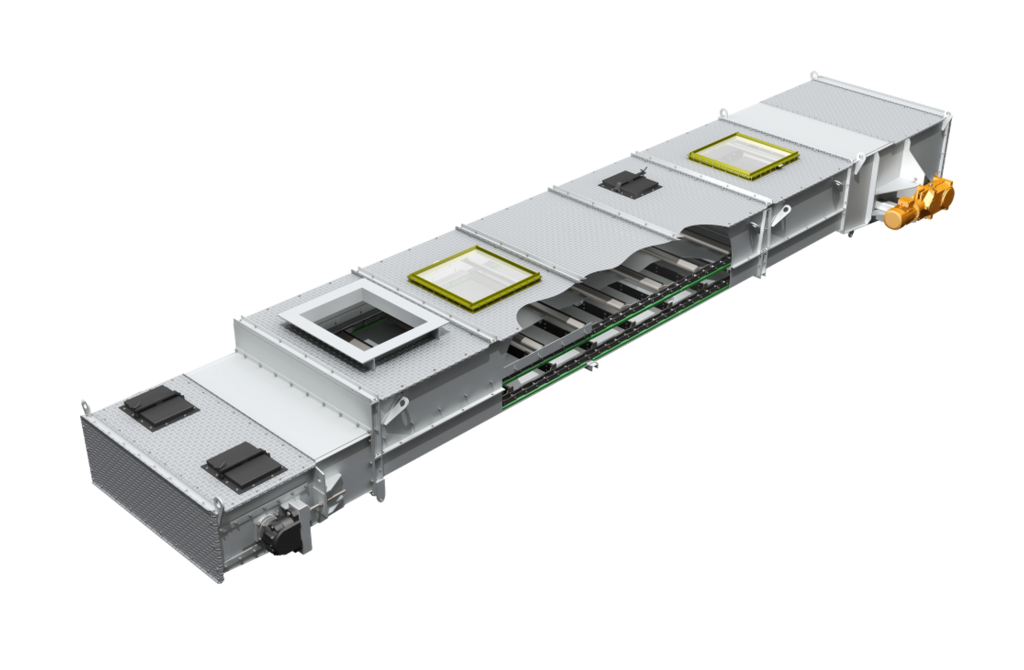

Drag Chain Conveyors

Drag Chain Conveyors are a safe and reliable solution for handling powdery and dusty bulk materials in industrial processes that require a continuous and even material flow. They can be used for instance in receiving the material and transporting it to intermediate storage, filling storage silos, discharging from storage or for intermediate transportation in the TYRANNOSAURUS® SRF production process.

Drag Chain Conveyors can be customised for a variety of materials in terms of composition and temperature.It is possible, for example, to include water-cooling designs and heatproof structures. Materials such as wood chips, bark, agro biomass, pellets, peat, SRF, coal, ash, cement, lime and minerals can be transported with Drag Chain Conveyors.

Main advantages:

- dust-tight and spillage-free construction,

- customised solutions based on modular engineering for fast and cost-effective installation,

- horisontal or inclined installations, or a combination of both,

- several inlet and outlet points,

- standard components and chain types,

- forged chains for heavy-duty applications,

- special chains for heavy-duty and demanding conditions (heatproof structures),

- possibility to include water-cooling designs and

- simple construction for straightforward maintenance.