Shredding Equipment

Shredders and Crushers

The

TYRANNOSAURUS® Waste and Biomass Shredders represent the core of our technical expertise. Combining smart technology, powerful performance, high throughput, and exceptional availability, these systems are the pinnacle of decades of material handling experience and superior Finnish engineering.

TYRANNOSAURUS® 9900 Primary Shredder

The TYRANNOSAURUS® 9900 Primary Waste Shredder is the largest and most intelligent single-rotor shredder on the market. It is designed for the industrial-scale shredding of almost all types of solid waste, from high-moisture Municipal Solid Waste (MSW) to dry Industrial and Commercial Waste (ICW) and various waste mixtures.

- The T9900 series primary shredder requires no pre-sorting, it can shred almost all solid waste into business-card-sized particles in a single pass, and possesses unparalleled processing capacity.

- Zero-gap cutting technology maintains high throughput, ensures longer service life for the cutting tools, and helps reduce operational costs.

- Massive Impact Protection technology is equivalent to automatically detecting and rejecting non-shreddable materials, thereby ensuring continuous high availability.

- Typical applications for the T9900 series shredders are the production of: chemical recycling feedstock, alternative fuel for cement kilns, and SRF for high-efficiency boilers.

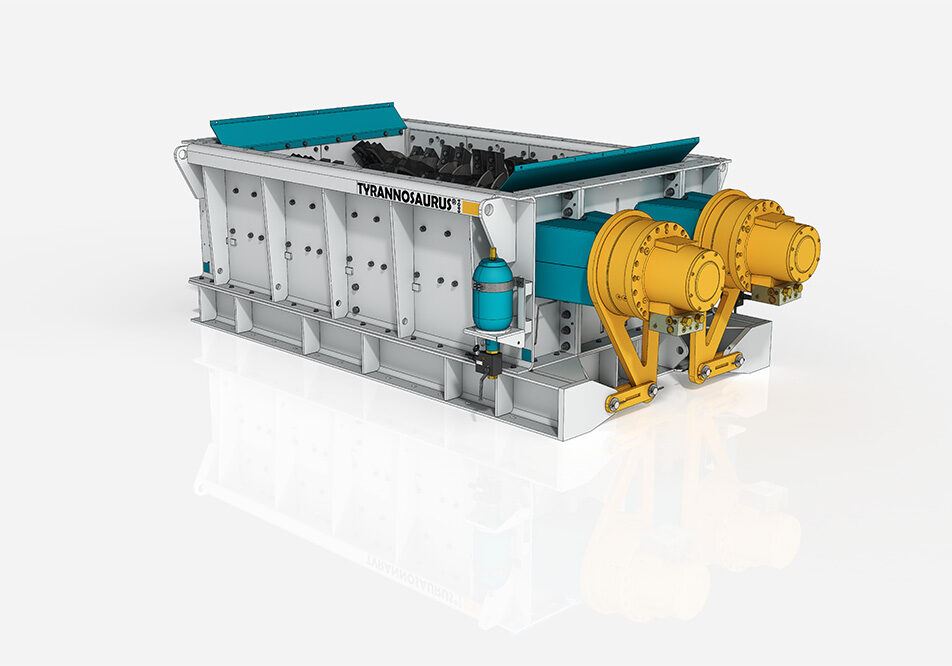

TYRANNOSAURUS® 8800 Primary Crusher

The TYRANNOSAURUS® 8800 Primary Crusher is a low-speed double-rotor primary waste shredder with a built-in screen. It is designed for the industrial-scale shredding of unsorted Municipal Solid Waste (MSW).

- The output particle size is uniform and controllable, with a size range of 80~200mm and high production capacity.

- Ease of maintenance and removal of non-shreddable items reduces operational expenses.

- The T8800 series can be equipped with hydraulic or electric drive units.

- Typical applications for the T8800 series shredders include: efficient shredding for waste-to-energy plants, alternative fuel for cement kilns, and RDF for high-efficiency boilers.

TYRANNOSAURUS® 7700 Primary Shredder

The TYRANNOSAURUS® 7700 Primary Shredder is a medium-speed single-rotor primary waste shredder equipped with a pusher. It is designed for the industrial-scale shredding of Industrial and Commercial Waste (ICW and C&I) as well as source-separated Municipal Solid Waste (MSW).

- The T7700 series plays an important role in RDF/SRF production lines where particle size is crucial. The equipment will be customized to produce particles in the 40~70mm range with high production capacity.

- Zero-gap cutting technology and impact protection features enable low operational expenses.

- The T7700 series offers multiple drive technology options. It can be equipped with either hydraulic or electric drive, both of which have their own advantages.

- Typical applications for the T7700 series shredders are the production of: alternative fuel for cement kilns and RDF for high-efficiency boilers.

TYRANNOSAURUS® 6600 Pre-Crusher

The TYRANNOSAURUS® 6600 Pre-Crusher is a low-speed double-rotor waste pre-shredder designed for the industrial-scale shredding of unsorted Municipal Solid Waste (MSW). It is typically used as a bag opener in the initial stage of the shredding process. The purpose of pre-shredding is to prepare waste for further treatment, which is why adding a T6600 pre-shredder in the waste refining process can improve waste separation efficiency.

- Robust structure designed for heavy-duty operations. Equally suitable for opening plastic bags before actual shredding, or for preliminary size reduction of bulky items.

- Achieves impressive throughput through a simple and robust structure.

- Operation and maintenance are easy and low-cost.

- The T6600 series is typically installed in: RDF manufacturing plants for power boilers, pre-treatment units for anaerobic digestion plants, pre-treatment plants delivering waste to chemical plants, and grate combustion equipment using primary shredders.

TYRANNOSAURUS® 7500 Oversize Shredder

The TYRANNOSAURUS® 7500 Oversize Shredder is a medium-speed single-rotor shredder. It is designed for the industrial-scale shredding of pre-shredded industrial and commercial waste (ICW and C&I), and is ideal for wood, textiles, cardboard, and plastics.

- The counter-knives are hydraulically held in place through the impact protection feature, thereby protecting the T7500 series from damage by non-shreddable items.

- The knife clearance can be adjusted to zero through zero-gap cutting technology, thereby maximizing the shredding capacity.

- The screen model can be selected according to the output particle size requirements.

- Typical applications for the T7500 series shredders include: waste shredding during the SRF production process and ensuring fuel quality for SRF end-users.

TYRANNOSAURUS® 1200/1200A FineShredder

The TYRANNOSAURUS® 1200/1200A FineShredder is an electric, high-speed, single-rotor shredder. It is designed for the industrial-scale refining of pre-shredded and separated solid waste, which needs to be reduced to 20~70mm to improve the combustibility of the fuel or optimize particle size for further processing.

- The T1200/1200A series fine shredders play an important role in RDF/SRF production lines where uniform particle size is a key factor. The T1200/1200A series fine shredders can be tailored to customer needs to produce the required particle size in the 20~70mm range with high throughput.

- Patented zero-gap cutting technology ensures that throughput, particle size, and quality are maintained even as the tools begin to wear. Optimal results are achieved even when cutting the thinnest waste materials.

- The impact protection feature reduces the need for process pauses and shortens actual downtime, allowing for easy and rapid removal of non-shreddable materials and preventing damage to the shredder.

- The T1200/1200A series fine shredders can produce: alternative fuel for cement kilns, feedstock for RDF pellet production, and feedstock for chemical production.